Turnkey Assembly

Turnkey Assembly at Nova Engineering is designed for teams who want a complete manufacturing solution from start to finish. This service includes component sourcing, procurement, incoming inspection, and full PCB assembly, allowing you to focus on design and testing instead of managing supply chain details. With more than 35 years of experience supporting electronic product development, we deliver fully assembled boards that are ready for immediate evaluation or deployment.

Full-Service PCB Assembly

Turnkey Assembly means Nova Engineering handles every stage of material and production management. You upload your design files and specifications—we take care of the rest. From ordering components to verifying part quality and maintaining traceability, our team ensures accuracy and consistency throughout the build process.

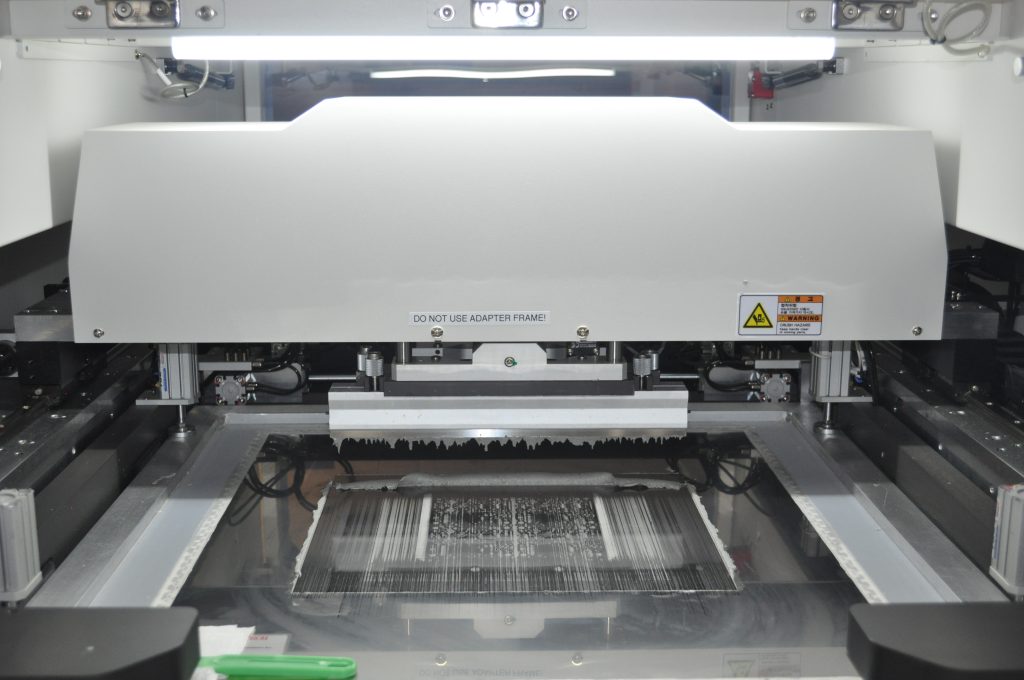

We support a wide range of technologies including high-density SMT, fine-pitch components, BGAs, through-hole devices, and mixed-technology boards. Whether your design is straightforward or highly complex, our production team assembles hardware according to your requirements with attention to detail at every step.

Design for Manufacturing

To help safeguard against delays or performance issues, we apply Design for Manufacturing (DFM) reviews at the beginning of each turnkey assembly project. As part of that process, we evaluate:

- Component availability and supply chain constraints

- Pad and footprint alignment

- Orientation and polarity indicators

- Solder mask, stencil, and land pattern considerations

- Potential assembly challenges or risk areas

- Any issues that could impact long-term reliability

Identifying these concerns early helps prevent redesign or sourcing complications once production begins, ensuring on-time delivery and reliable boards.

Flexible Low-Volume Capabilities

Every project follows its own development timeline. We support builds from initial low-volume runs to larger quantities as designs move closer to production readiness. Prototyping phases often shift quickly, and our manufacturing approach adapts to those changes without compromising accuracy or quality. By maintaining inventory control throughout the build, we help ensure alignment with your engineering requirements and uninterrupted progress during testing and evaluation.

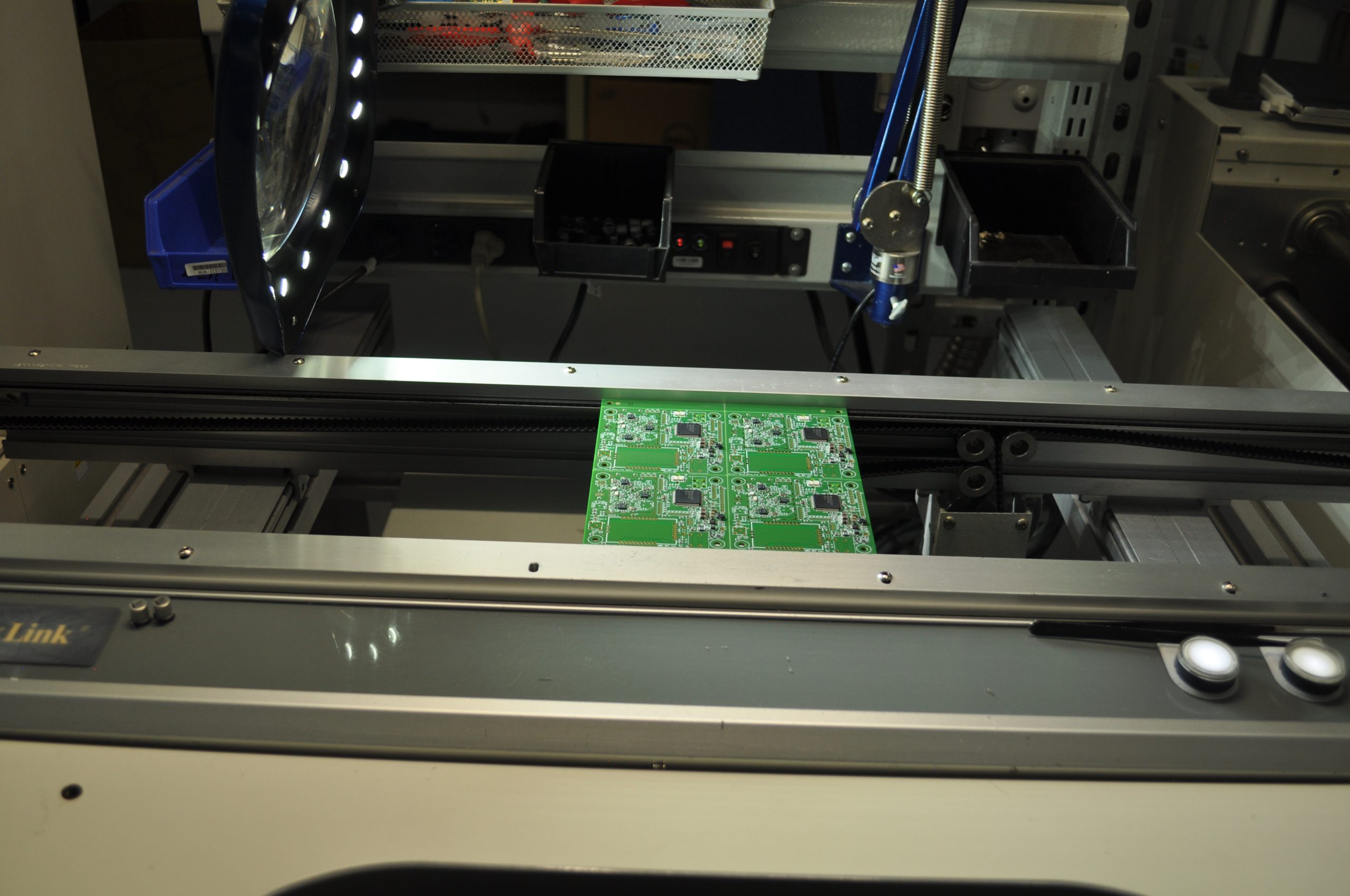

Inspection and Functional Verification

Quality control is integrated into our workflow. Incoming materials are verified before assembly, and boards undergo inspection processes such as automated optical inspection (AOI) to confirm proper placement and soldering. Customer-defined test procedures or fixtures can also be incorporated to verify performance under real-world conditions. These checks help ensure each assembly is ready for immediate use in continued validation, qualification, or final product integration.

Seamless Transition to Production

Once a design is proven, we can transition work into production using the same documentation and process controls established during early builds. Keeping a consistent manufacturing partner from prototypes through higher-volume production reduces onboarding delays and avoids variation that comes with changing suppliers. This continuity helps support predictable output, long-term reliability, and a smooth ramp into ongoing production demands.

Start Your Next Project With Nova

Turnkey Assembly at Nova Engineering offers a dependable way to receive fully finished boards without the burden of component sourcing and material logistics. We help streamline development cycles so your team can stay focused on engineering and product refinement. Contact us today to get your project started.