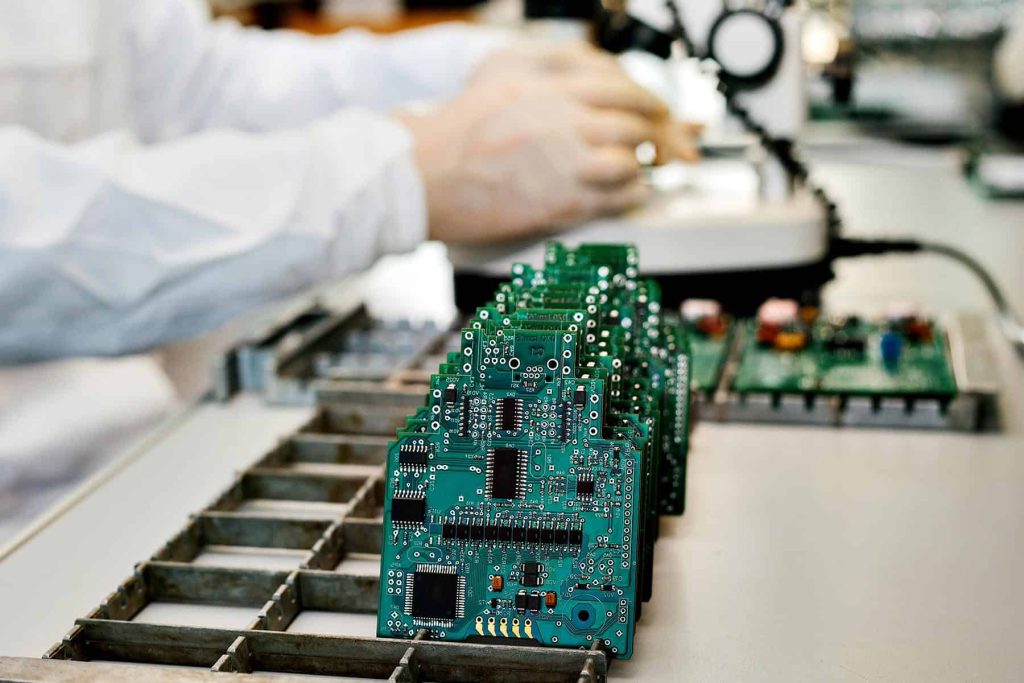

Prototype Assembly

At Nova Engineering, we support product development teams by providing accurate, reliable prototype assembly that helps validate designs before full production. Our focus is on quality, manufacturability, and rapid iteration to keep your project moving without unnecessary delays. Whether you need a single board built or a small run for testing and evaluation, our team has the capabilities to assemble complex printed circuit board designs with precision.

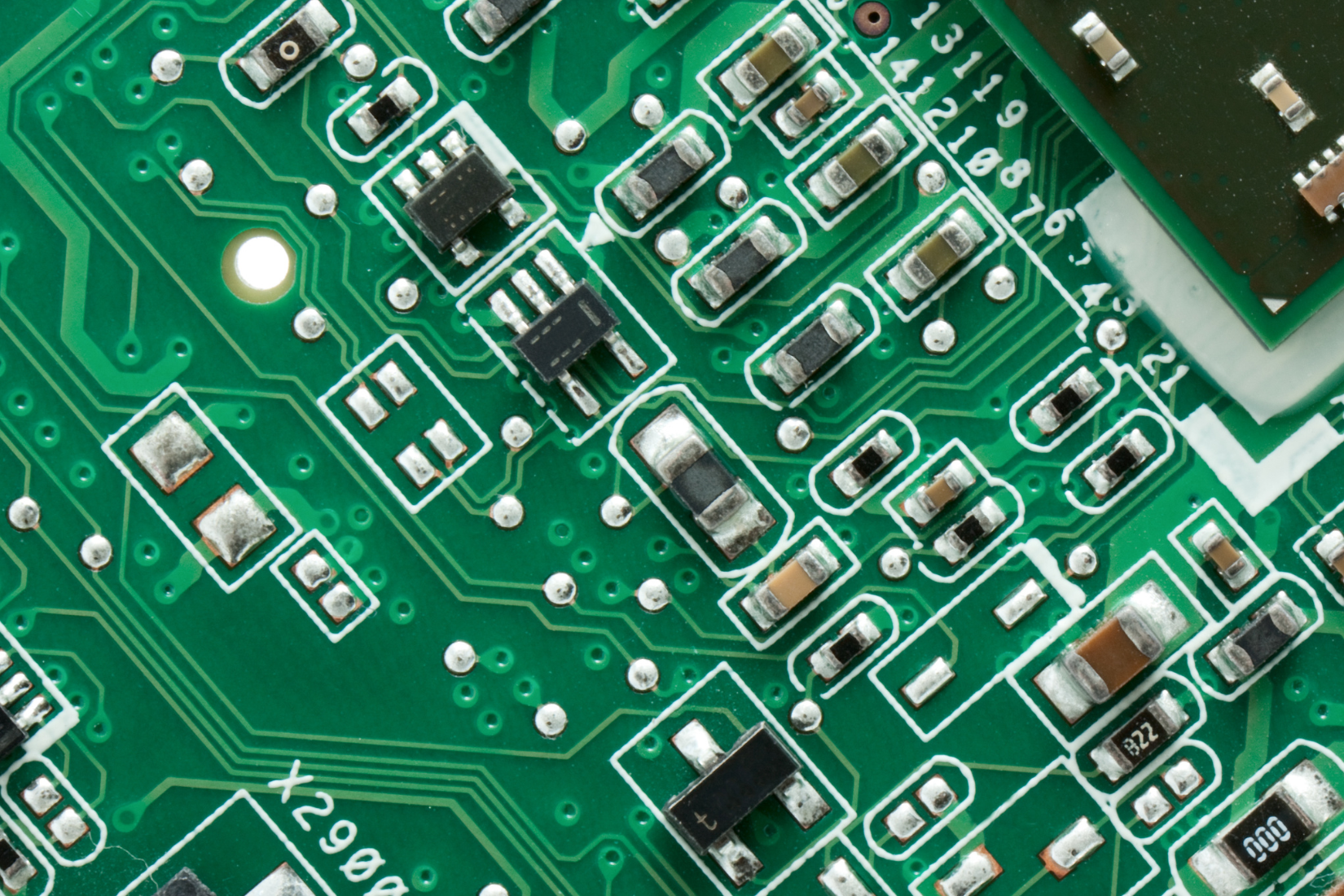

Precision Assembly for Any Design

Every prototype is unique. We work with a wide range of PCB layouts, component types, and assembly requirements. This includes surface mount parts, fine-pitch devices, ball grid arrays, through-hole components, and mixed-technology builds. Regardless of board size or component density, we assemble hardware according to your specifications and ensure the result reflects the intent of your engineering design.

Our technicians evaluate each assembly step carefully to ensure correct placement, proper soldering, polarity orientation, and consistent overall quality. Early prototypes are often critical for functional testing and verification, so attention to detail is built into our process.

Design for Manufacturing

Prototype success goes beyond placing components on a board. To help reduce risks in later production stages, we apply Design for Manufacturing (DFM) methods during review and assembly. As part of this process, we look for:

- Pad size, spacing, and rotation issues

- Inaccurate or mismatched PCB footprints

- Component orientation or polarity concerns

- Solder mask or copper constraints

- Features that may create soldering challenges

- Any manufacturability issues that could cause delays or rework

By identifying potential problems early, we help minimize redesign cycles and ensure long-term product reliability.

Flexible Low-Volume Capabilities

Prototyping often requires frequent adjustments, new revisions, and multiple evaluation cycles. We support low-volume builds with fast turnarounds so your team can focus on refining product performance. Whether your design is ready for first-article validation or is still evolving, we can accommodate multiple versions and provide ongoing support.

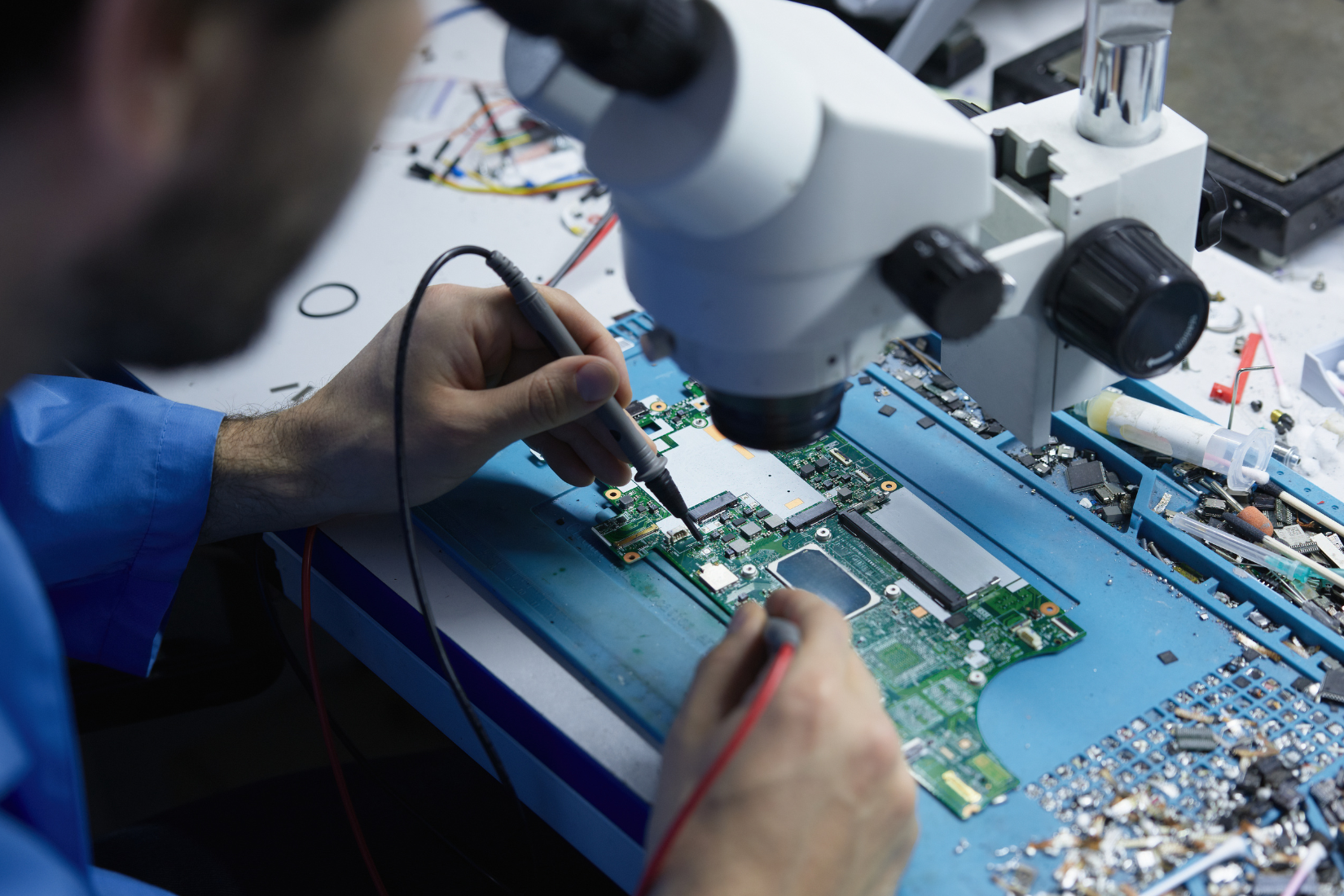

Inspection and Functional Verification

Functional verification is a key part of successful prototype development. We offer inspection and testing options to confirm build quality and performance, including automated optical inspection (AOI) and additional testing based on customer-supplied requirements or fixtures. These steps help ensure prototypes are ready for engineering testing or field evaluations.

Seamless Transition to Production

Once a design is finalized, we can transition your assembly into production with consistent processes and traceable documentation. Keeping the same partner from prototype through full manufacturing helps avoid disruptions and supports stable production control from the start. This ensures a dependable move into production with minimal changes needed.

Start Your Next Project With Nova

Our Prototype Assembly service enables a dependable path from concept to functional hardware and onward to full production when ready. We help ensure that your assembly works as designed while allowing you to move through development stages efficiently and confidently. Contact us today to get your project started.