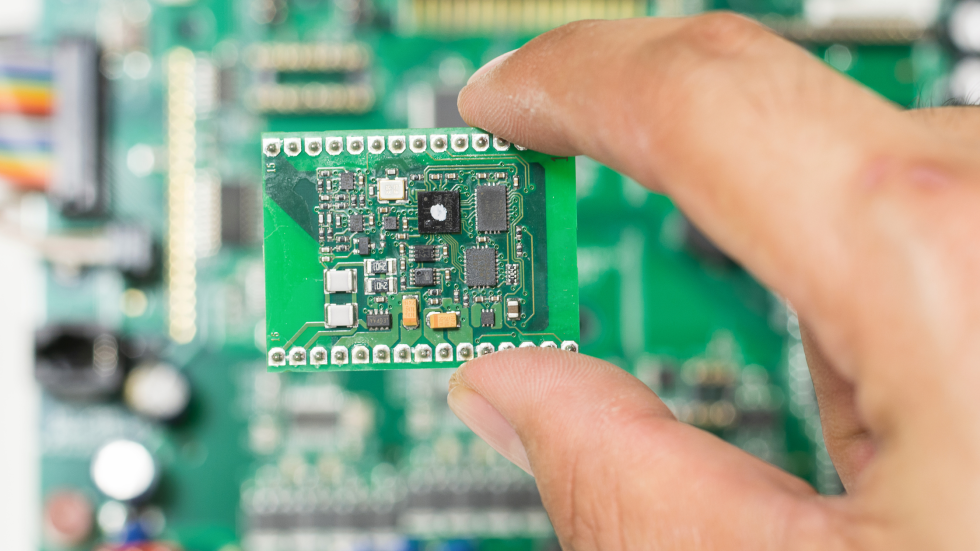

PCB Assembly

Nova Engineering provides complete PCB assembly services to support product development from early prototypes through production. Our capabilities cover a wide range of board technologies, package types, and volume requirements, allowing customers to move efficiently from design to working hardware. Whether you need support sourcing materials or prefer to supply your own components, our team ensures every assembly meets your technical specifications and performance goals.

Comprehensive Assembly Capabilities

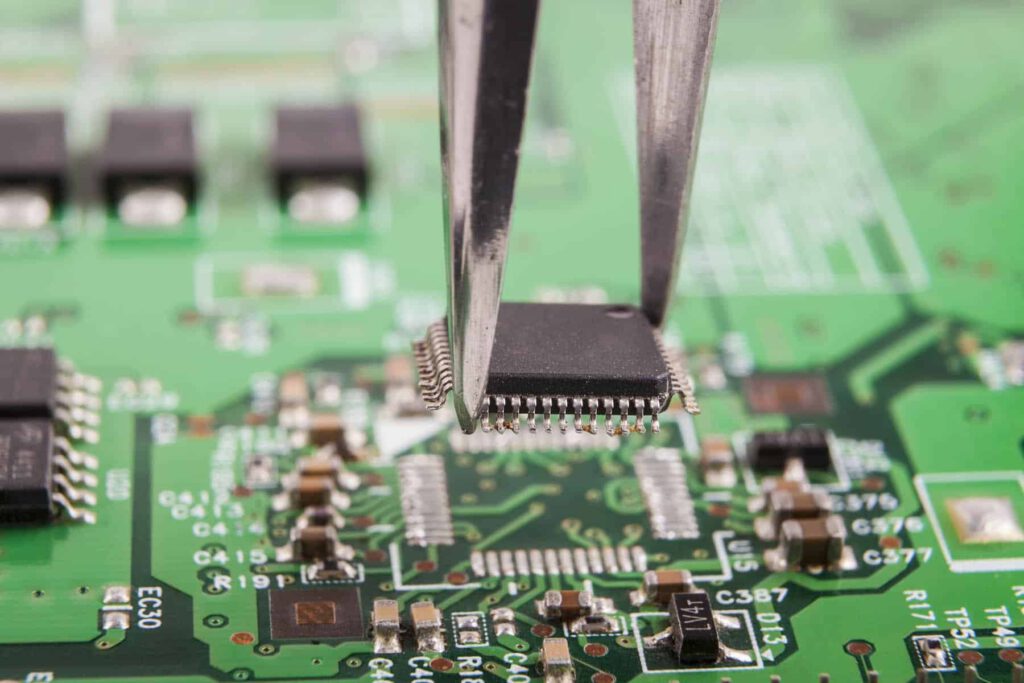

We assemble printed circuit boards using surface mount, through-hole, and mixed-technology designs. Our technicians handle standard and fine-pitch components, BGAs, micro BGAs, connectors, and specialized parts that require careful placement and inspection.

Each assembly project receives careful attention to workmanship, solder integrity, and orientation accuracy. Consistent quality at this stage helps support reliable testing, evaluation, and integration into larger systems.

Design for Manufacturing

To help ensure a stable and efficient assembly process, we incorporate Design for Manufacturing (DFM) reviews as a standard part of our workflow. During this review, we verify:

- Footprint compatibility and land pattern sizing

- Component polarity and placement orientation

- Solder mask and paste alignment

- Pad spacing and clearance

- Thermal and manufacturability concerns

- Features that could impact long-term reliability

Proactive evaluation helps reduce rework, delays, and unexpected issues once hardware is in testing or field use.

Prototype Assembly

Our prototype assembly capabilities support early-stage builds, engineering validation, and iterative design improvements. We accommodate rapid changes, multiple revisions, and low-volume requests without long lead times—helping engineering teams move confidently from concept to functional hardware while maintaining consistent quality across each version.

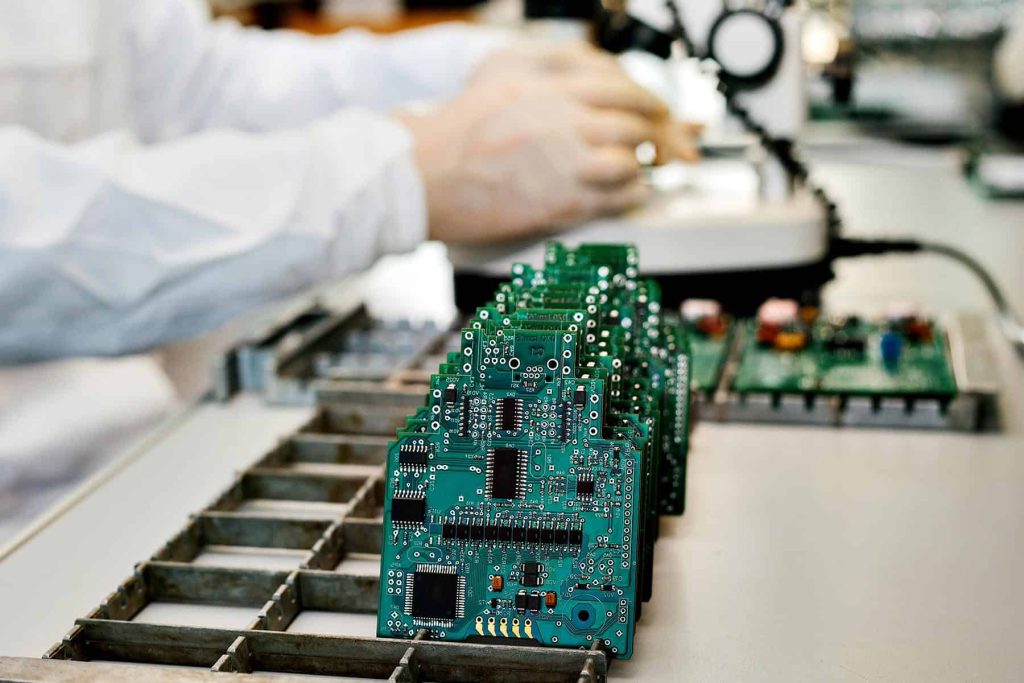

Turnkey Assembly

For customers who want a complete sourcing and assembly solution, our turnkey service manages every stage of material procurement and production. We handle component sourcing, verification, and traceability to ensure your boards are assembled on schedule and ready for immediate testing or integration, eliminating the need to manage supply chain logistics internally.

Consigned Assembly

For customers who prefer to supply some or all components, our consigned and partially consigned options provide flexibility while maintaining controlled, reliable assembly. You may leverage your own approved vendors, proprietary components, or existing inventory, with Nova sourcing any additional parts needed to complete the build.

Start Your Next Project With Nova

PCB Assembly at Nova Engineering supports every phase of development with reliable processes, technical experience, and the flexibility needed to maintain momentum. Our goal is to help ensure each assembly performs as designed while simplifying the path from concept to production. Contact us today to get your project started.