Consigned Assembly

Consigned Assembly at Nova Engineering allows customers to maintain full control over their component procurement while relying on our team for professional PCB assembly. You supply the parts and materials—such as components, bare boards, and any specialty hardware—and we manage the complete assembly process using proven quality standards and inspection methods.

Component-Controlled Assembly

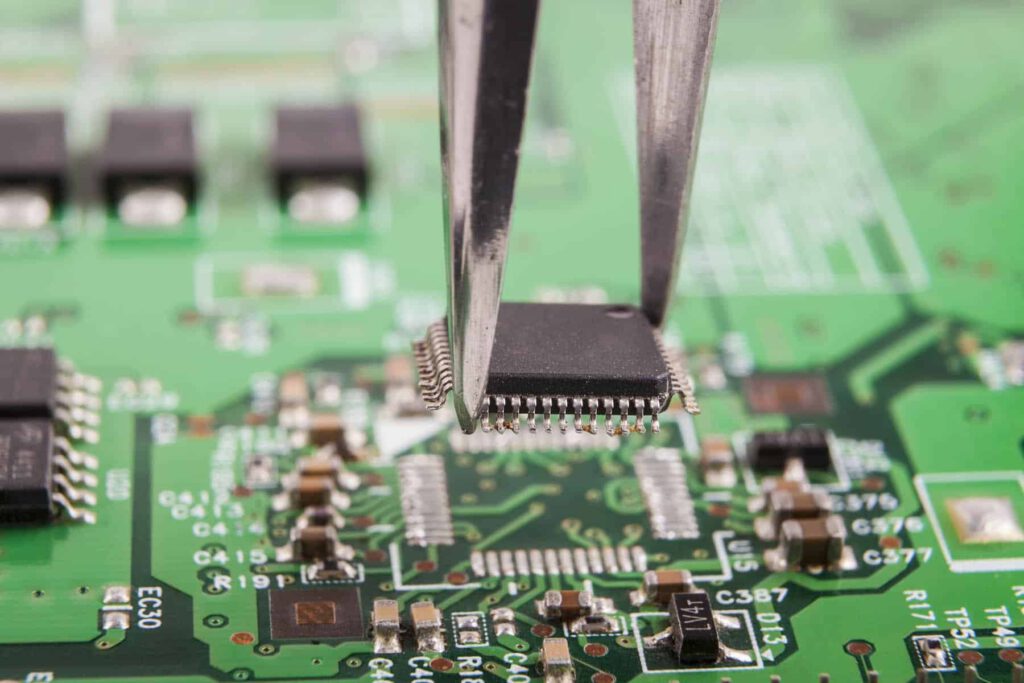

Consigned assembly is ideal for companies with specific vendor relationships, approved parts lists, or components already in stock. We work with the materials you provide and assemble boards according to your design files and specifications. Our technicians ensure proper handling, placement accuracy, and soldering quality so the finished assemblies meet the performance and reliability you expect.

We accommodate surface mount, through-hole, fine-pitch, and mixed-technology designs. Throughout the build, materials are carefully tracked and managed to avoid shortages or errors.

Design for Manufacturing

Even when components are provided by the customer, we still apply Design for Manufacturing (DFM) methods to support a smooth and predictable assembly process. During review and production, we check for:

- Fit and alignment of provided components and footprints

- Proper orientation and polarity verification

- Pad and land pattern compatibility

- Any assembly risks related to thermal, spacing, or handling requirements

- Issues that could compromise soldering or long-term operation

These evaluations help reduce build interruptions and ensure that boards function properly during testing or end use.

Flexible Low-Volume Capabilities

Consigned assembly supports development at any stage, from engineering validation through early production. We assist with initial builds, prototype revisions, and ongoing work using customer-owned materials while maintaining clear communication throughout the process. This helps ensure alignment with your engineering requirements and allows any material or assembly concerns to be resolved quickly to keep testing and refinement moving forward.

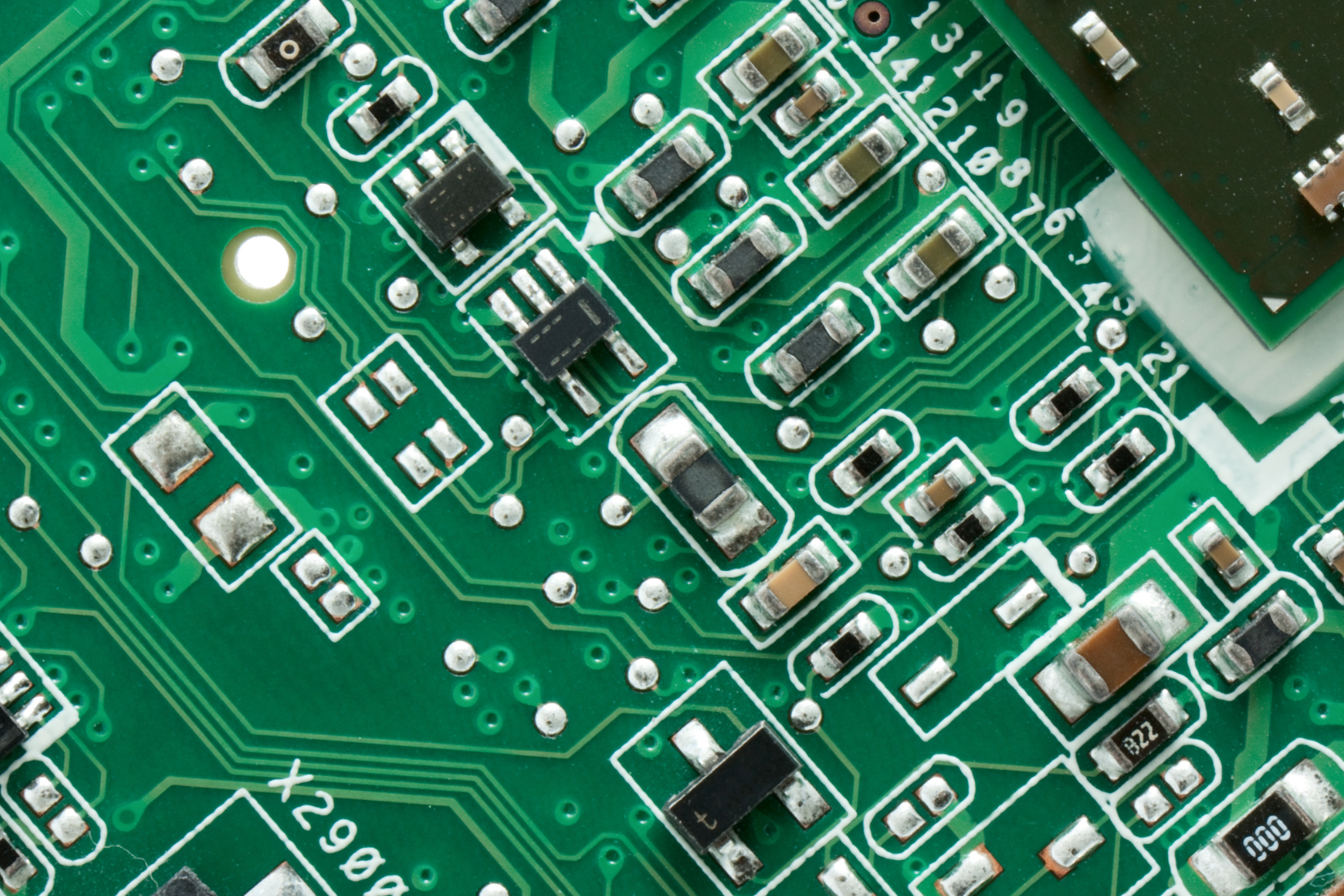

Inspection and Functional Verification

Quality assurance remains a key part of our workflow. Boards assembled using customer-supplied components go through the same inspection standards applied to turnkey builds, including automated optical inspection (AOI) where applicable. Optional functional testing based on your supplied procedures can also be incorporated. These combined checks help verify performance and readiness for evaluation, qualification, or integration into larger systems.

Smooth Transition to Full Production

As designs progress and demand increases, Nova Engineering can scale builds into production using the same documentation and process controls established during development. Keeping a single assembly partner throughout the product lifecycle reduces variation and prevents delays that often occur when switching suppliers mid-project. This continuity supports predictable output and a reliable path into sustained production.

Partially Consigned Assembly

Some customers prefer to supply select components—often long-lead, proprietary, or specialized parts—while leaving the remaining sourcing to Nova Engineering. Our partially consigned option supports that approach. You send the materials you want to manage; we procure and track the rest. This hybrid model provides flexibility while maintaining efficient assembly planning and supply chain continuity.

Start Your Next Project With Nova

Consigned Assembly at Nova Engineering supports teams that want the benefits of expert PCB assembly while retaining direct control over component supply. Whether you provide all or only some of the parts, our focus is on delivering boards that meet your technical and performance requirements. Contact us today to get your project started.